English

English-

English

English -

Français

Français -

日本語

日本語 -

Deutsch

Deutsch -

tiếng Việt

tiếng Việt -

Italiano

Italiano -

Nederlands

Nederlands -

ภาษาไทย

ภาษาไทย -

Polski

Polski -

한국어

한국어 -

Svenska

Svenska -

magyar

magyar -

Malay

Malay -

বাংলা ভাষার

বাংলা ভাষার -

Dansk

Dansk -

Suomi

Suomi -

हिन्दी

हिन्दी -

Pilipino

Pilipino -

Türkçe

Türkçe -

Gaeilge

Gaeilge -

العربية

العربية -

Indonesia

Indonesia -

Norsk

Norsk -

تمل

تمل -

český

český -

ελληνικά

ελληνικά -

український

український -

Javanese

Javanese -

فارسی

فارسی -

தமிழ்

தமிழ் -

తెలుగు

తెలుగు -

नेपाली

नेपाली -

Burmese

Burmese -

български

български -

ລາວ

ລາວ -

Latine

Latine -

Қазақша

Қазақша -

Euskal

Euskal -

Azərbaycan

Azərbaycan -

Slovenský jazyk

Slovenský jazyk -

Македонски

Македонски -

Lietuvos

Lietuvos -

Eesti Keel

Eesti Keel -

Română

Română -

Slovenski

Slovenski -

मराठी

मराठी -

Srpski језик

Srpski језик -

Español

Español -

Português

Português

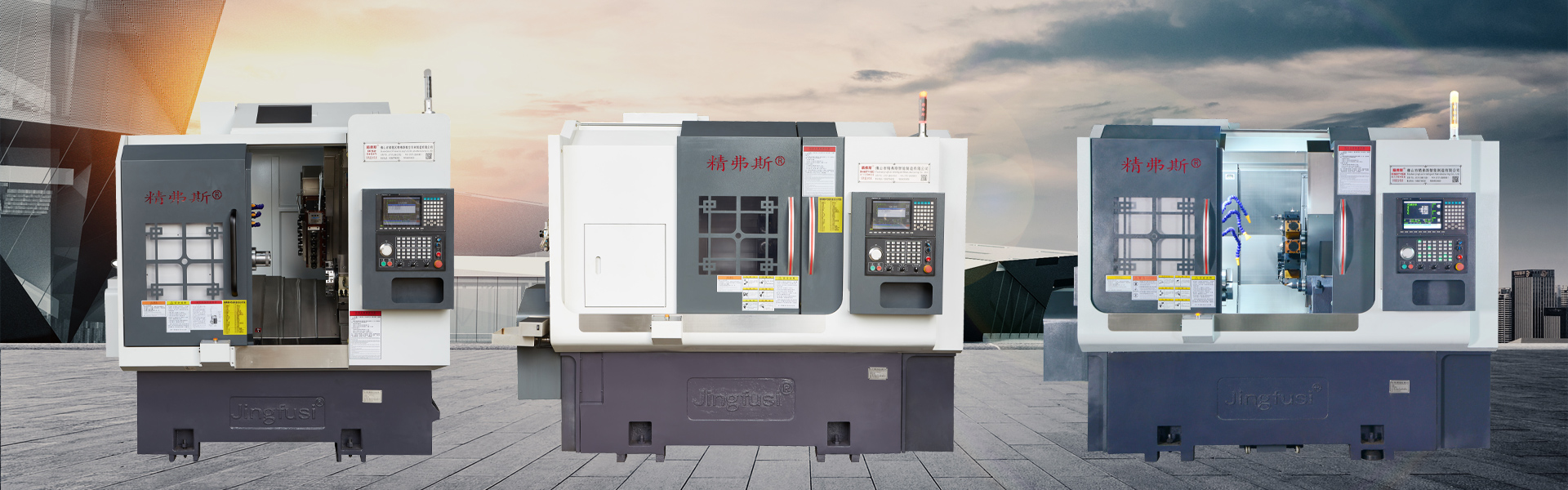

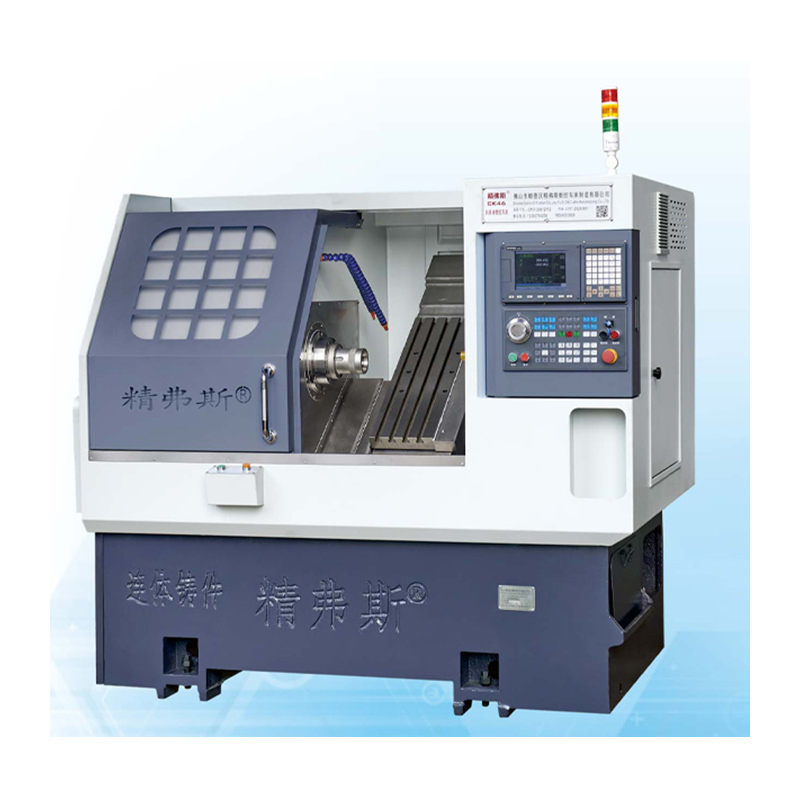

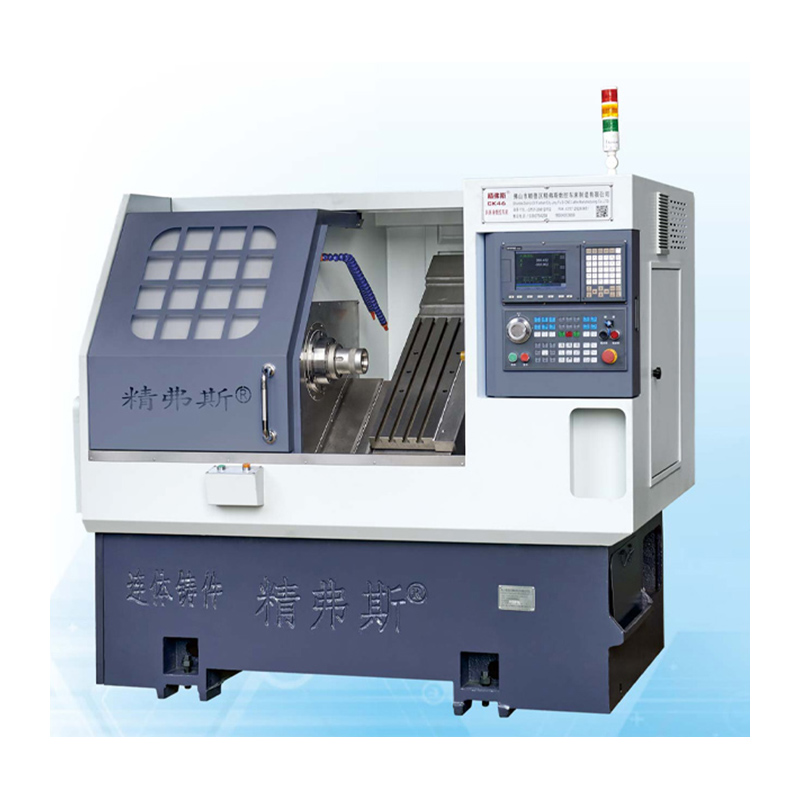

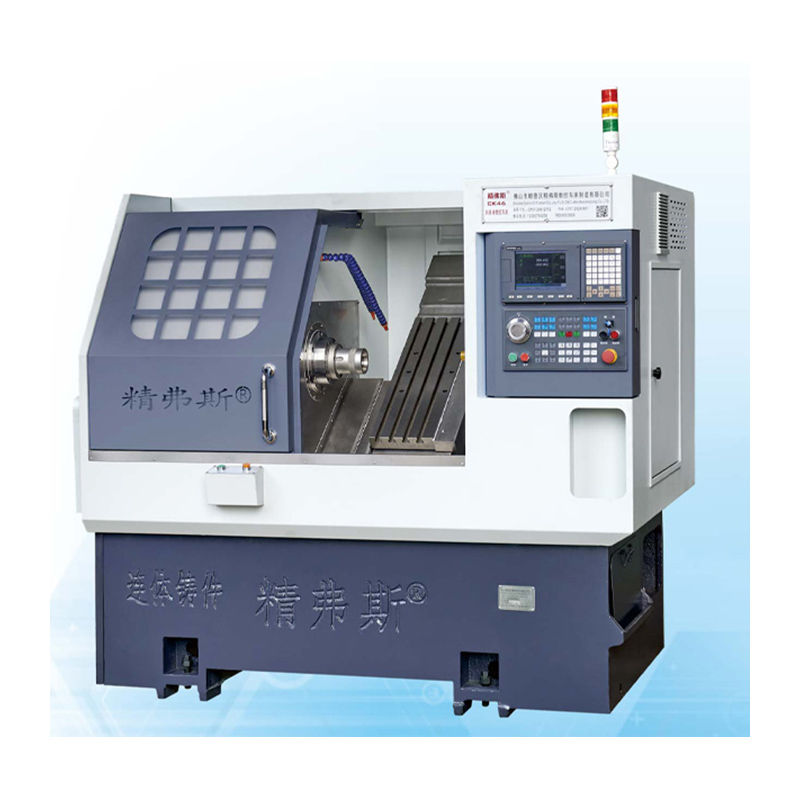

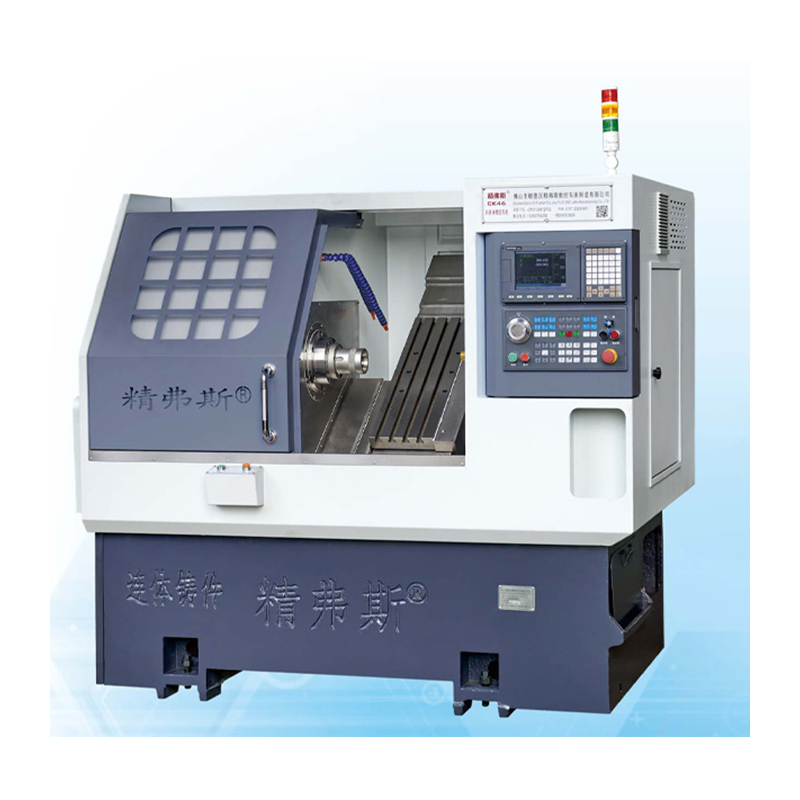

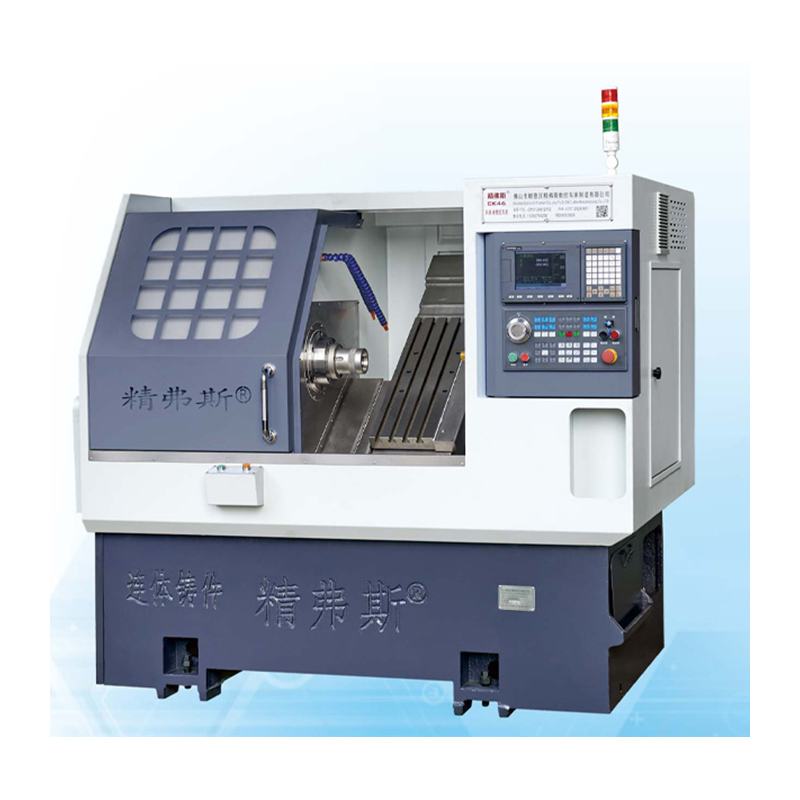

Inclined Slant bed Turning CNC Lathe Machine

The CK46 Inclined Slant bed Turning CNC Lathe Machine is an improvement and upgrade of Jingfusi® on the original basis. On the basis of inheriting the high processing performance and easy operation of the original model, it has been developed with a fully enclosed inclined bed design and greater operation Space, higher processing speed and precision CNC machine tools that are easier to adjust and maintain.

Model:CK46

Send Inquiry

Product Description

This Inclined Slant bed Turning CNC Lathe Machine adopts a 45-degree inclined bed design and a super-rigid torque structure to ensure that the bed is not easily deformed during heavy-load cutting. The tilt angle makes installation, replacement and inspection easier. High-precision ball screws and spindles. Guaranteed highest precision and surface gloss.

Jingfusi® Slant Bed CNC Lathe Machine Features:

Optimal Design: This Inclined Slant bed Turning CNC Lathe Machine features a 35-degree slant bed design, providing enhanced rigidity and stability for precision machining.

Efficient Chip Handling: The machine offers a substantial chip conveying capacity, allowing customers the flexibility to select either front or rear chip removal, ensuring convenience in the machining process.

Screw Pre-Stretching: Incorporating a screw pre-stretching structure, this lathe optimizes machining accuracy and reliability.

Gang-Type Tool Post: Equipped with a gang-type tool post, this lathe supports the use of multiple tools for increased efficiency and versatility in various machining operations.

Product Details

Parameter List

| project | unit | CK46 | CK52 | CK76 | |

| Maximum turning length | mm | 350 | |||

| Maximum turning diameter on the bed | mm | Ø 500 | |||

| Maximum turning diameter on the skateboard | mm | Ø 160 | |||

| Bed inclination | ° | 35° | |||

| Effective travel of X/Z axis | mm | Diameter 1000/400 | |||

| X/Z axis screw specifications | mm | 32 | |||

| X/Z axis rail specifications | mm | 35 | |||

| X/Z-axis motor power | KW | 1.3 | |||

| Maximum fast movement of X/Z axis | m/min | 24 | |||

| Machine tool length X width X height | mm | 2100X1580X1800 | |||

| Total weight of the entire machine | KG | 2600 | |||

| Knife number | fix | 8 | |||

| Square knife size | mm | 20X20 | |||

| Round hole cutter size | mm | Ø20 | |||

| Total power | kw | 13 | 13 | 16 | |

| Average power consumption | kw/h | 2 | 2 | 2.5 | |

| main shaft | Spindle end face form |

|

A2 - 5 | A2 - 6 | A2 -8 |

| Maximum spindle speed | r/min | 6000 (set to 4500) | 4200(set to 3500) | 3200(set to 2500) | |

| Spindle motor power | KW | 7.5 | 7.5 | 11 | |

| Rated torque of spindle motor | Nm | 47.8Nm | 47.8Nm | 72Nm | |

| Maximum bar passing diameter | mm | Ø 45 | Ø 51 | Ø 75 | |

Machine Tool Accuracy

| Machine accuracy,Jingfus factor standard : | ||||

| Major test item | Schematic diagram |

Detection method |

Factory standard |

|

| Spindle radial beat, |

|

Detect runout of outer cone | 0.0025 | |

| X-axis repeat position |

|

Detect repeated positioning of the X-axis. Note: First predict about 50 times to offset the error of the cold engine and hot engine, and then detect the repeated positioning. | 0.0025 | |

| Z-axis repeat position |

|

Detect repeated positioning on the Z axis. Note: First predict about 50 times to offset the error of the cold engine and hot engine, and then detect the repeated positioning. | 0.0025 | |

| If the customer wants to test the ISO or VD1 accuracy of X/Z/Y axis, it shall be determined at the time of writing the contract. The customer must test this item at the same time of the initial acceptance of Jingfusi Factory. | ||||

Hot Tags: Inclined Slant bed Turning CNC Lathe Machine, China, Manufacturers, Suppliers, Factory, Quality, Price List

Product Tag

Send Inquiry

Please feel free to fill your inquiry in the form below. We will reply you in 24 hours.

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy