English

English-

English

English -

Français

Français -

日本語

日本語 -

Deutsch

Deutsch -

tiếng Việt

tiếng Việt -

Italiano

Italiano -

Nederlands

Nederlands -

ภาษาไทย

ภาษาไทย -

Polski

Polski -

한국어

한국어 -

Svenska

Svenska -

magyar

magyar -

Malay

Malay -

বাংলা ভাষার

বাংলা ভাষার -

Dansk

Dansk -

Suomi

Suomi -

हिन्दी

हिन्दी -

Pilipino

Pilipino -

Türkçe

Türkçe -

Gaeilge

Gaeilge -

العربية

العربية -

Indonesia

Indonesia -

Norsk

Norsk -

تمل

تمل -

český

český -

ελληνικά

ελληνικά -

український

український -

Javanese

Javanese -

فارسی

فارسی -

தமிழ்

தமிழ் -

తెలుగు

తెలుగు -

नेपाली

नेपाली -

Burmese

Burmese -

български

български -

ລາວ

ລາວ -

Latine

Latine -

Қазақша

Қазақша -

Euskal

Euskal -

Azərbaycan

Azərbaycan -

Slovenský jazyk

Slovenský jazyk -

Македонски

Македонски -

Lietuvos

Lietuvos -

Eesti Keel

Eesti Keel -

Română

Română -

Slovenski

Slovenski -

मराठी

मराठी -

Srpski језик

Srpski језик -

Español

Español -

Português

Português

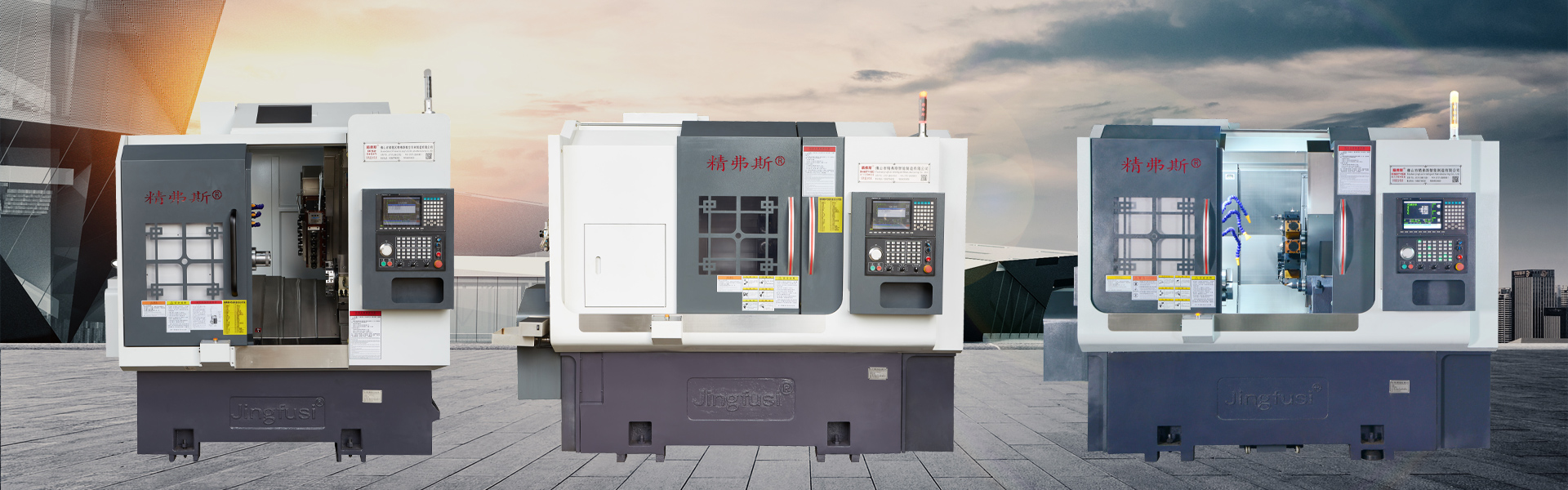

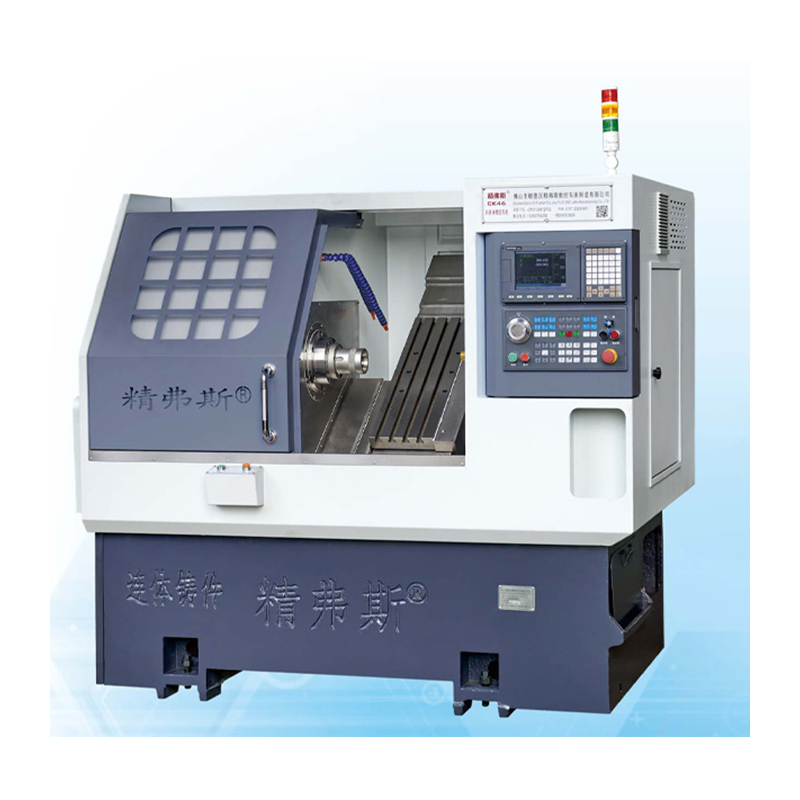

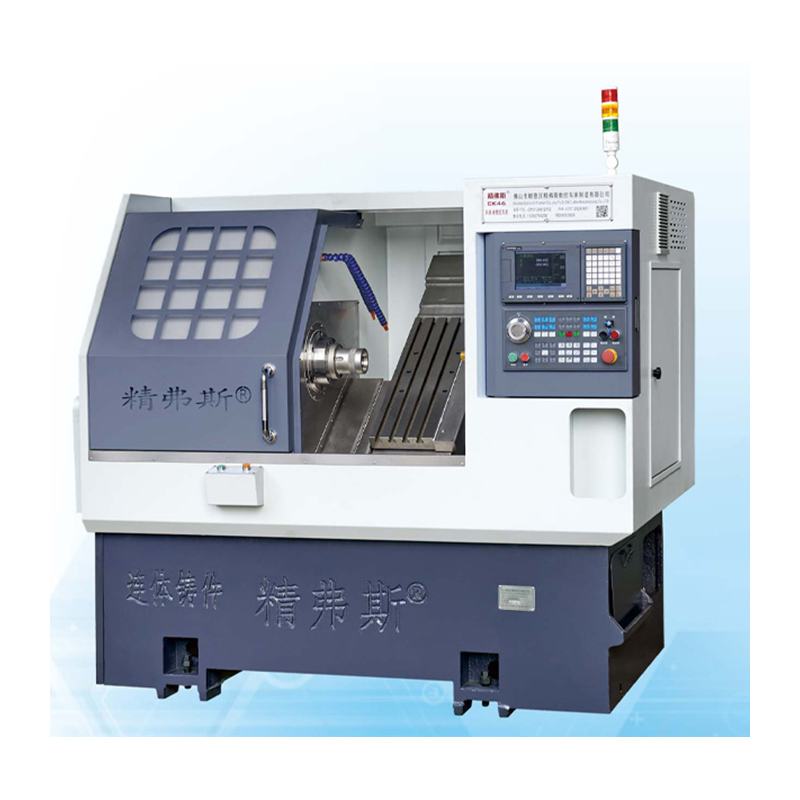

CNC Inclined Bed Lathe Machine

The Jingfusi® high quality CNC Inclined Bed Lathe Machine has the characteristics of convenient chip removal, complete functions, excellent performance, high rigidity, high efficiency, and high precision. Mainly used in auto parts, plumbing valves, molds and other industries.

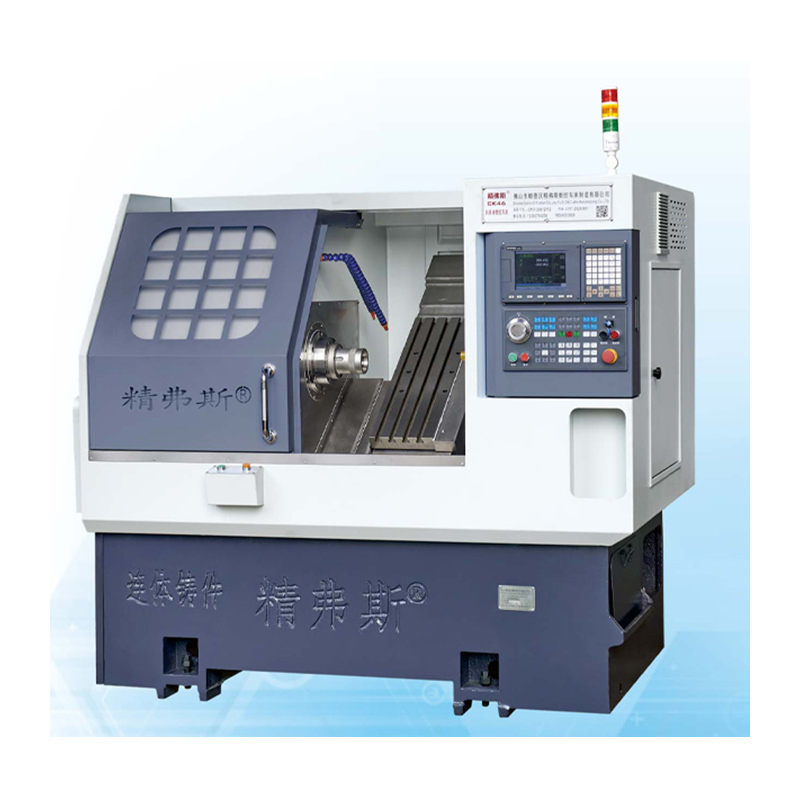

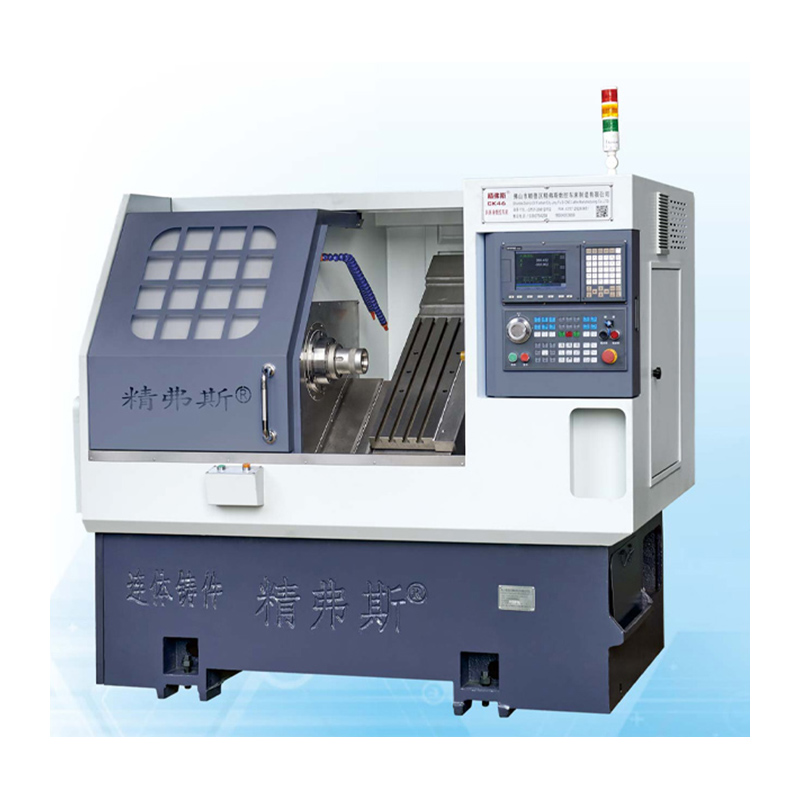

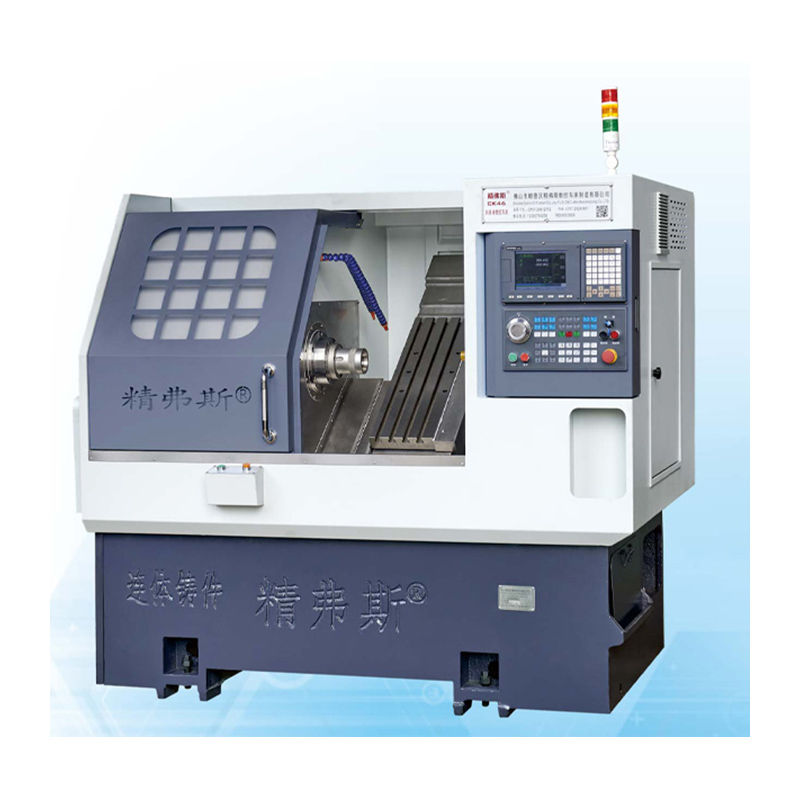

Model:CK46

Send Inquiry

Product Description

Jingfusi® CNC Inclined Bed Lathe Machine is mainly used in auto parts, plumbing valves, molds and other industries. It is also suitable for batch processing of shafts, discs and other parts with complex sizes, various sizes and high precision requirements. It can automatically complete chip processing of internal and external circles, grooves, cones, spherical surfaces, various metric and inch threads and other rotary bodies. The castings are all made of resin sand, which has undergone aging treatment and has good stability, high strength and good accuracy retention.

Product Details

Parameter List

| project | unit | CK46 | CK52 | CK76 | |

| Maximum turning length | mm | 350 | |||

| Maximum turning diameter on the bed | mm | Ø 500 | |||

| Maximum turning diameter on the skateboard | mm | Ø 160 | |||

| Bed inclination | ° | 35° | |||

| Effective travel of X/Z axis | mm | Diameter 1000/400 | |||

| X/Z axis screw specifications | mm | 32 | |||

| X/Z axis rail specifications | mm | 35 | |||

| X/Z-axis motor power | KW | 1.3 | |||

| Maximum fast movement of X/Z axis | m/min | 24 | |||

| Machine tool length X width X height | mm | 2100X1580X1800 | |||

| Total weight of the entire machine | KG | 2600 | |||

| Knife number | fix | 8 | |||

| Square knife size | mm | 20X20 | |||

| Round hole cutter size | mm | Ø20 | |||

| Total power | kw | 13 | 13 | 16 | |

| Average power consumption | kw/h | 2 | 2 | 2.5 | |

| main shaft | Spindle end face form |

|

A2 - 5 | A2 - 6 | A2 -8 |

| Maximum spindle speed | r/min | 6000 (set to 4500) | 4200(set to 3500) | 3200(set to 2500) | |

| Spindle motor power | KW | 7.5 | 7.5 | 11 | |

| Rated torque of spindle motor | Nm | 47.8Nm | 47.8Nm | 72Nm | |

| Maximum bar passing diameter | mm | Ø 45 | Ø 51 | Ø 75 | |

Machine Tool Accuracy

| Machine accuracy,Jingfus factor standard : | ||||

| Major test item | Schematic diagram |

Detection method |

Factory standard |

|

| Spindle radial beat, |

|

Detect runout of outer cone | 0.0025 | |

| X-axis repeat position |

|

Detect repeated positioning of the X-axis. Note: First predict about 50 times to offset the error of the cold engine and hot engine, and then detect the repeated positioning. | 0.0025 | |

| Z-axis repeat position |

|

Detect repeated positioning on the Z axis. Note: First predict about 50 times to offset the error of the cold engine and hot engine, and then detect the repeated positioning. | 0.0025 | |

| If the customer wants to test the ISO or VD1 accuracy of X/Z/Y axis, it shall be determined at the time of writing the contract. The customer must test this item at the same time of the initial acceptance of Jingfusi Factory. | ||||

Hot Tags: CNC Inclined Bed Lathe Machine, China, Manufacturers, Suppliers, Factory, Quality, Price List

Send Inquiry

Please feel free to fill your inquiry in the form below. We will reply you in 24 hours.

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy