English

English-

English

English -

Français

Français -

日本語

日本語 -

Deutsch

Deutsch -

tiếng Việt

tiếng Việt -

Italiano

Italiano -

Nederlands

Nederlands -

ภาษาไทย

ภาษาไทย -

Polski

Polski -

한국어

한국어 -

Svenska

Svenska -

magyar

magyar -

Malay

Malay -

বাংলা ভাষার

বাংলা ভাষার -

Dansk

Dansk -

Suomi

Suomi -

हिन्दी

हिन्दी -

Pilipino

Pilipino -

Türkçe

Türkçe -

Gaeilge

Gaeilge -

العربية

العربية -

Indonesia

Indonesia -

Norsk

Norsk -

تمل

تمل -

český

český -

ελληνικά

ελληνικά -

український

український -

Javanese

Javanese -

فارسی

فارسی -

தமிழ்

தமிழ் -

తెలుగు

తెలుగు -

नेपाली

नेपाली -

Burmese

Burmese -

български

български -

ລາວ

ລາວ -

Latine

Latine -

Қазақша

Қазақша -

Euskal

Euskal -

Azərbaycan

Azərbaycan -

Slovenský jazyk

Slovenský jazyk -

Македонски

Македонски -

Lietuvos

Lietuvos -

Eesti Keel

Eesti Keel -

Română

Română -

Slovenski

Slovenski -

मराठी

मराठी -

Srpski језик

Srpski језик -

Español

Español -

Português

Português

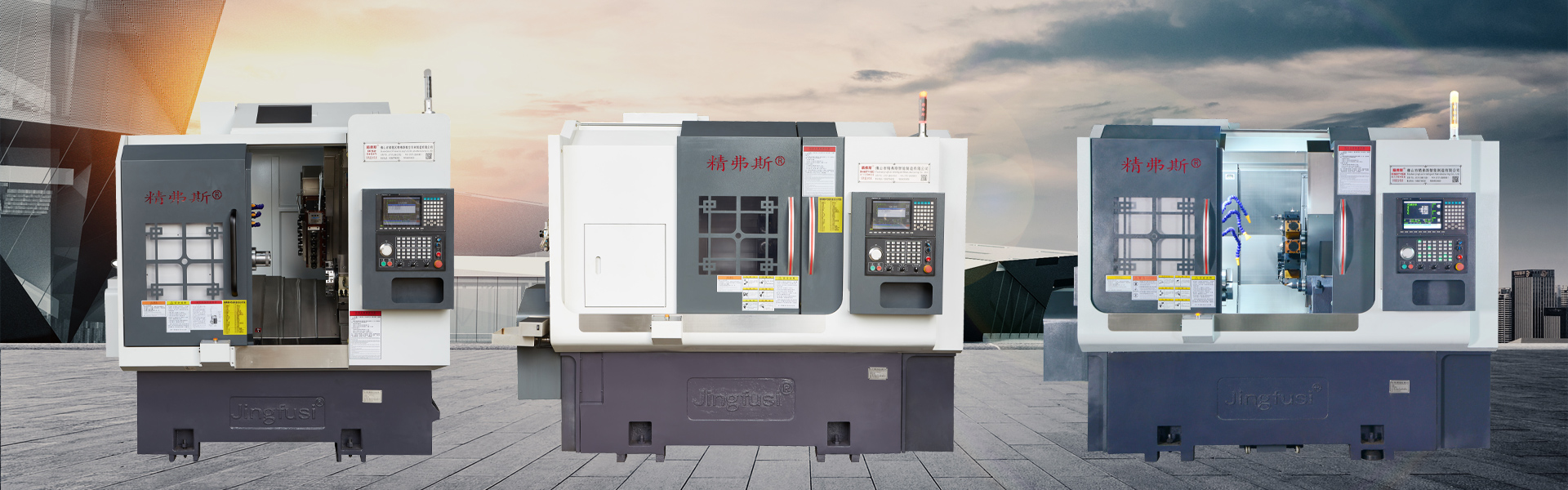

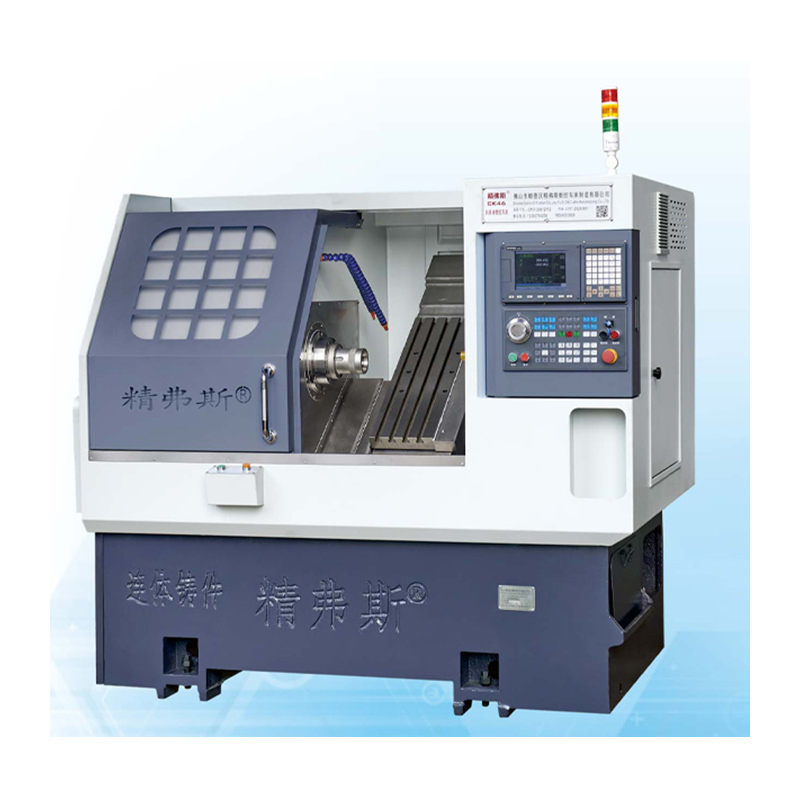

Turning-Milling Compound Cnc Lathe

A defining aspect of the Jingfusi® Turning-Milling Compound Cnc Lathe is its rock-solid and resilient construction. This ensures that, regardless of the most demanding workloads, it maintains unwavering accuracy and consistent performance. Boasting a heavy-duty bed and linear guide rails, this machine is crafted for longevity and delivers dependable outcomes that surpass all expectations.

Model:CK76DTY

Send Inquiry

Turning-Milling Compound CNC Lathe Production Introduction

The high-quality Turning-Milling Compound CNC Lathe supplied by Jingfusi® manufacturer is the ultimate solution for precision machining and fabrication.

Fundamentally, the core value of this cutting-edge Turning-Milling Compound Cnc Lathe is to provide unparalleled precision, efficiency and versatility to cope with the rigors of modern manufacturing processes. Our CNC Mill-Turn Lathe uses cutting-edge technology to accurately and quickly perform a variety of operations such as turning, milling, drilling and tapping.

Not only that, Turning-Milling Compound Cnc Lathe is also equipped with a high-speed spindle motor to ensure faster and more accurate cutting speeds during the processing. This feature is particularly critical in complex machining tasks because it can significantly reduce production cycle time while maintaining high accuracy.

What's more, the built-in CNC control system of this machine tool adopts a user-friendly design, making it easy and fast for both novice and experienced operators to complete machining setup and operation. This feature makes it an ideal choice for workshops, small businesses and even large manufacturing plants.

Another highlight of the Turning-Milling Compound Cnc Lathe is its powerful processing capabilities. With its large swing on the bed and large distance between centers, it can easily handle large workpieces of various sizes and shapes to meet almost any machining needs.

| item | Model of lathe | unit | CK46DTY | CK52DTY |

| Processing scope | Maximum rotation diameter of the spindle | mm | Ø 600 | |

| Maximum turning outer circle length | mm | 300 | ||

| Maximum bar diameter | mm | Ø 45 | Ø 55 | |

| principal axis | Maximum spindle speed | r/min | 6000(setting 4500) | 4200(setting 3500) |

| Spindle head type |

|

A2 - 5 | A2 - 6 | |

| Spindle through-hole diameter | mm | Ø 56 | Ø 66 | |

| feed | X/Z/Y axis maximum stroke | mm | 800/400/±60 | |

| 90 ° power head passing through the center of the spindle | mm | 60 | ||

| Maximum fast movement of X/Z/Y axis | m/min | 24(setting 18) / 24(setting 18) /15(setting 12) | ||

| X/Z/Y axis screw rod | mm | 32/32/32 | ||

| X/Z/Y axis roller track | mm | 35/35/35 | ||

|

Power turret |

Power turret model (power turret) | BMT | BMT45,Optional BMT55 | |

| Power head collet | ER | ER25 | ||

| Fixed tool holder size | mm | 25X25 | ||

| Bore holder shank diameter | mm | Ø25 | ||

| Tailstock | Main motor power/torque | KW/Nm | 7.5 KW/rated 47Nm | 11KW/rated 72Nm |

| X/Z/Y axis motor power/torque | KW/Nm | yaskawa 1.8KW/11.5N. Optional new generation2.4 KW/rated 11.5Nm | ||

| Maximum speed of turret power motor | r/min | 80000°(power head ≤7000 change,90°power head ≤6000 change) | ||

| Power head motor power/torque | KW/Nm | 8.5 KW/rated 16.5Nm | ||

| Power/torque of turret tool changing motor | KW/Nm | New generation1.0 KW /3.1NM | ||

| other | Spindle positioning brake device |

|

hydraulic pressure | |

| Bed inclination | ° | 35° | ||

| Machine tool length X width X height | mm | 2200X1500X1900 | ||

| Total weight of the entire machine | KG | 3900KG | ||

| Total power | kw | 15 | ||

| Average power consumption | kw/h | 3 | ||

| Machine accuracy,Jingfus factor standard : | ||||||||

| Major test item | Schematic diagram | Factory standard | ||||||

| Spindle radial beat |

|

Detect runout of outer cone | 0.0035 | |||||

| X-axis repeat position |

|

Detect repeated positioning of the X-axis. Note: First predict about 50 times to offset the error of the cold engine and hot engine, and then detect the repeated positioning. | 0.003 | |||||

| Z-axis repeat position |

|

Detect repeated positioning on the Z axis. Note: First predict about 50 times to offset the error of the cold engine and hot engine, and then detect the repeated positioning. | 0.003 | |||||

| Y-axis repeat position |

|

Detect repeated positioning on the Y axis. Note: First predict about 50 times to offset the error of the cold engine and hot engine, and then detect the repeated positioning. | 0.004 | |||||

| C axis repeat position |

|

Detect the repositioning of the C-axis fixed point, note: first predict about 50 times to offset the error of the cold engine and hot engine, and then detect the repeated positioning | 20 arc seconds | |||||

| C axis position rotary |

|

Detect the random position accuracy of the C-axis, note: first predict about 50 times to offset the error of the cold engine and hot engine, and then check the repeated settings | 72 arc seconds | |||||

| Power head clamping beat |

|

Cone beat | 0.015 | |||||

| Power head clamping beat |

|

Clamping beating | 0.01 | |||||

| If the customer wants to test the ISO or VD1 accuracy of X/Z/Y axis, it shall be determined at the time of writing the contract. The customer must test this item at the same time of the initial acceptance of Jingfusi Factory. | ||||||||