English

English-

English

English -

Français

Français -

日本語

日本語 -

Deutsch

Deutsch -

tiếng Việt

tiếng Việt -

Italiano

Italiano -

Nederlands

Nederlands -

ภาษาไทย

ภาษาไทย -

Polski

Polski -

한국어

한국어 -

Svenska

Svenska -

magyar

magyar -

Malay

Malay -

বাংলা ভাষার

বাংলা ভাষার -

Dansk

Dansk -

Suomi

Suomi -

हिन्दी

हिन्दी -

Pilipino

Pilipino -

Türkçe

Türkçe -

Gaeilge

Gaeilge -

العربية

العربية -

Indonesia

Indonesia -

Norsk

Norsk -

تمل

تمل -

český

český -

ελληνικά

ελληνικά -

український

український -

Javanese

Javanese -

فارسی

فارسی -

தமிழ்

தமிழ் -

తెలుగు

తెలుగు -

नेपाली

नेपाली -

Burmese

Burmese -

български

български -

ລາວ

ລາວ -

Latine

Latine -

Қазақша

Қазақша -

Euskal

Euskal -

Azərbaycan

Azərbaycan -

Slovenský jazyk

Slovenský jazyk -

Македонски

Македонски -

Lietuvos

Lietuvos -

Eesti Keel

Eesti Keel -

Română

Română -

Slovenski

Slovenski -

मराठी

मराठी -

Srpski језик

Srpski језик -

Español

Español -

Português

Português

Home

>

Products > Turning and Milling Combined Machine

>

High-Speed Turret Turning and Milling Machine

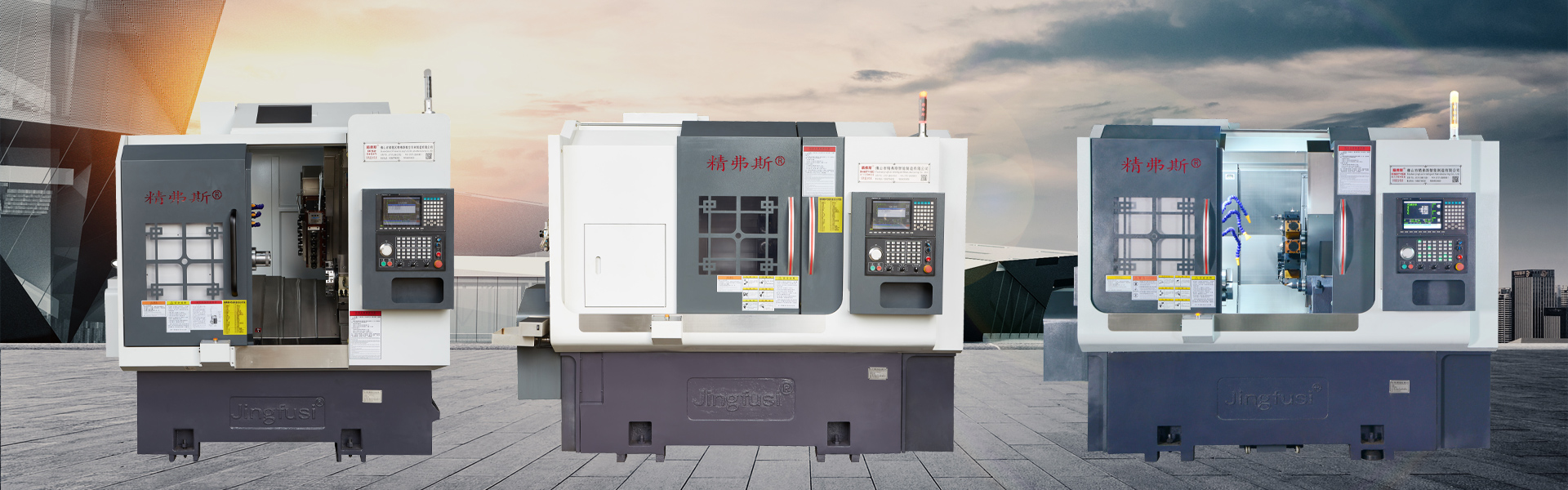

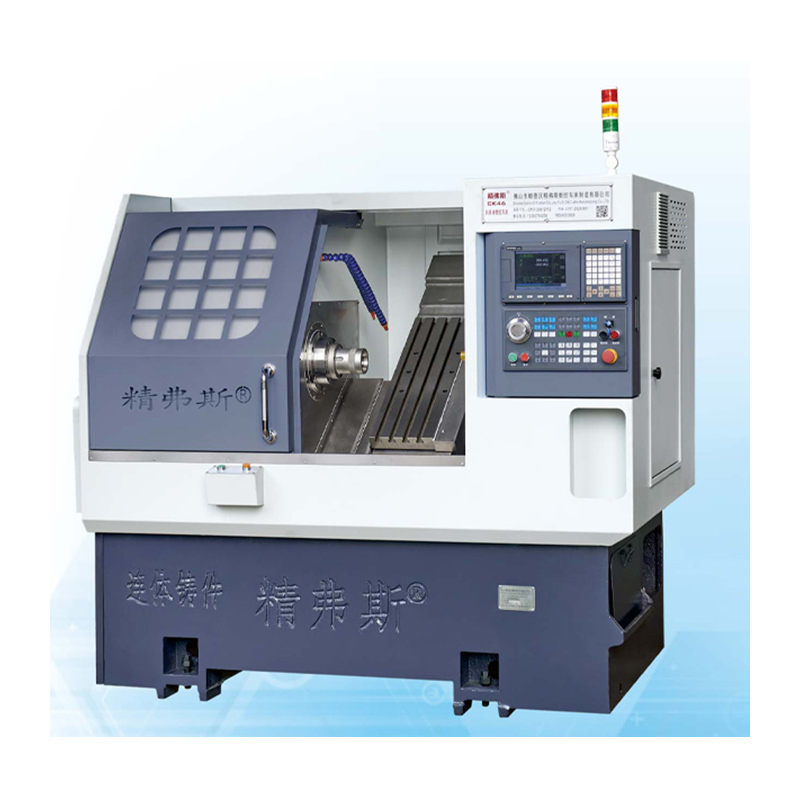

High-Speed Turret Turning and Milling Machine

The high-speed turret turning and milling machine is a sophisticated CNC (Computer Numerical Control) machine tool that combines the capabilities of a lathe (turning) and a milling machine. These machines are designed for precision machining operations and are often used in industries where high accuracy and efficiency are essential.You can rest assured to buy High-Speed Turret Turning and Milling Machine from our factory and we will offer you the best after-sale service and timely delivery.

Model:CK52DTY

Send Inquiry

Product Description

As the professional manufacturer, we would like to provide you High-Speed Turret Turning and Milling Machine. And we will offer you the best after-sale service and timely delivery.

Here are some key features and characteristics of high-speed turret turning and milling machines:

Turret Tooling: These machines typically have a tool turret that can hold multiple cutting tools. The turret can be indexed automatically to select the appropriate tool for a specific machining operation, reducing setup time and increasing versatility.

Turning Capability: High-speed turret turning and milling machines can perform turning operations, which involve rotating a workpiece while a cutting tool removes material to create cylindrical or conical shapes. This is useful for producing parts with rotational symmetry.

Milling Capability: These machines can also perform milling operations, which involve removing material from a workpiece by moving a cutting tool in various directions. Milling allows for the creation of complex shapes, features, and contours.

CNC Control: Most modern turret turning and milling machines are controlled by CNC systems. CNC technology enables precise control of tool movements and machining processes, ensuring accuracy and repeatability.

Live Tooling: Some machines are equipped with live tooling capabilities. Live tooling allows milling operations to be performed while the workpiece is rotating, expanding the machine's capabilities and reducing the need for multiple setups.

Automatic Tool Changes: Many of these machines feature automatic tool changers, which can quickly and automatically swap out tools in the turret, allowing for continuous machining without manual tool changes.

Applications: High-speed turret turning and milling machines find applications in industries that require high-precision components, such as aerospace, automotive, medical device manufacturing, and the production of complex mechanical parts.

In summary, a high-speed turret turning and milling machine is a versatile CNC machine tool that combines turning and milling capabilities with a focus on high-speed machining. They are used in industries where the production of complex and precise components is essential, and their advanced features make them valuable assets for modern manufacturing processes.

Turning Capability: High-speed turret turning and milling machines can perform turning operations, which involve rotating a workpiece while a cutting tool removes material to create cylindrical or conical shapes. This is useful for producing parts with rotational symmetry.

Milling Capability: These machines can also perform milling operations, which involve removing material from a workpiece by moving a cutting tool in various directions. Milling allows for the creation of complex shapes, features, and contours.

CNC Control: Most modern turret turning and milling machines are controlled by CNC systems. CNC technology enables precise control of tool movements and machining processes, ensuring accuracy and repeatability.

Live Tooling: Some machines are equipped with live tooling capabilities. Live tooling allows milling operations to be performed while the workpiece is rotating, expanding the machine's capabilities and reducing the need for multiple setups.

Automatic Tool Changes: Many of these machines feature automatic tool changers, which can quickly and automatically swap out tools in the turret, allowing for continuous machining without manual tool changes.

Applications: High-speed turret turning and milling machines find applications in industries that require high-precision components, such as aerospace, automotive, medical device manufacturing, and the production of complex mechanical parts.

In summary, a high-speed turret turning and milling machine is a versatile CNC machine tool that combines turning and milling capabilities with a focus on high-speed machining. They are used in industries where the production of complex and precise components is essential, and their advanced features make them valuable assets for modern manufacturing processes.

Machine Travel Diagram

Product Details

Parameter List

| item | Model of lathe | unit | CK52DTY | CK76DTY | CK46DTY |

| Processing scope | Maximum rotation diameter of the spindle | mm | Ø 700 | ||

| Maximum turning outer circle length | mm | 520 | |||

| Maximum bar diameter | mm | Ø 55 | Ø 72 | Ø 45 | |

| principal axis | Maximum spindle speed | r/min | 4200(setting 3500) | 3200(setting 2000) | 6000(设定4500) |

| Spindle head type |

|

A2 - 6 | A2 -8 | A2 - 5 | |

| Spindle through-hole diameter | mm | Ø 66 | Ø 86 | Ø 56 | |

| feed | X/Z/Y axis maximum stroke | mm | 260/500/±60 | ||

| 90 ° power head passing through the center of the spindle | mm | 30 | |||

| Maximum fast movement of X/Z/Y axis | m/min | 24(setting 16)/ 24(setting 16)/14(setting 8) | |||

| X/Z/Y axis screw rod | mm | 40 | |||

| X/Z/Y axis roller track | mm | 35/45/35 | |||

|

Power turret |

Power turret model (power turret) | BMT | BMT55 | ||

| Power head collet | ER | ER32 | |||

| Fixed tool holder size | mm | 25X25 | |||

| Bore holder shank diameter | mm | Ø32 | |||

| electrical machinery | Main motor power/torque | KW/Nm | 11KW/rated 72Nm | 15KW/rated 98Nm | 7.5 KW/rated 47Nm |

| X/Z/Y axis motor power/torque | KW/Nm | yaskawa 2.9 KW /18.6Nm,Optional new generation3.1 KW /15Nm | |||

| Power/torque of turret power head motor | KW/Nm | New generation 3.1 KW/15NM | |||

| Maximum speed of turret power motor | r/min | 6000(setting 4000) ,Common speed≤4000 | |||

| Power head motor power/torque | KW/Nm | 3.1 KW/15NM | |||

| Power/torque of turret tool changing motor | KW/Nm | New generation1.0 KW /3.1NM | |||

| Tailstock | Tailstock stroke | mm | 520 | ||

|

Maximum hydraulic stroke of tailstock |

mm | 100 | |||

| Tailstock top needle cone hole taper | MK | mohs 5# | |||

| Maximum distance between tip and chuck | mm | 690 | |||

| other | Spindle positioning brake device |

|

Hydraulic, optional programmable | ||

| Bed inclination | ° | 30° or 15° | |||

| Machine tool length X width X height | mm | 2500X1680X1900 | |||

| Total weight of the entire machine | KG | 5000KG | |||

| Total power | kw | 20 | |||

| Average power consumption | kw/h | 3 | |||

Machine Tool Accuracy

| Machine accuracy,Jingfus factor standard : | ||||||||

| Major test item | Schematic diagram |

Detection method |

Factory standard |

|||||

| Spindle radial beat |

|

Detect runout of outer cone | 0.0035 | |||||

| X-axis repeat position |

|

Detect repeated positioning of the X-axis. Note: First predict about 50 times to offset the error of the cold engine and hot engine, and then detect the repeated positioning. | 0.003 | |||||

| Z-axis repeat position |

|

Detect repeated positioning on the Z axis. Note: First predict about 50 times to offset the error of the cold engine and hot engine, and then detect the repeated positioning. | 0.003 | |||||

| Y-axis repeat position |

|

Detect repeated positioning on the Y axis. Note: First predict about 50 times to offset the error of the cold engine and hot engine, and then detect the repeated positioning. | 0.004 | |||||

| C axis repeat position |

|

Detect the repositioning of the C-axis fixed point, note: first predict about 50 times to offset the error of the cold engine and hot engine, and then detect the repeated positioning | 20 arc seconds | |||||

| C axis position rotary |

|

Detect the random position accuracy of the C-axis, note: first predict about 50 times to offset the error of the cold engine and hot engine, and then check the repeated settings | 72 arc seconds | |||||

| Power head clamping beat |

|

Cone beat | 0.015 | |||||

| Power head clamping beat |

|

Clamping beating | 0.01 | |||||

| If the customer wants to test the ISO or VD1 accuracy of X/Z/Y axis, it shall be determined at the time of writing the contract. The customer must test this item at the same time of the initial acceptance of Jingfusi Factory. | ||||||||

Hot Tags: High-Speed Turret Turning and Milling Machine, China, Manufacturers, Suppliers, Factory, Quality, Price List

Product Tag

Send Inquiry

Please feel free to fill your inquiry in the form below. We will reply you in 24 hours.

Related Products

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy