English

English-

English

English -

Français

Français -

日本語

日本語 -

Deutsch

Deutsch -

tiếng Việt

tiếng Việt -

Italiano

Italiano -

Nederlands

Nederlands -

ภาษาไทย

ภาษาไทย -

Polski

Polski -

한국어

한국어 -

Svenska

Svenska -

magyar

magyar -

Malay

Malay -

বাংলা ভাষার

বাংলা ভাষার -

Dansk

Dansk -

Suomi

Suomi -

हिन्दी

हिन्दी -

Pilipino

Pilipino -

Türkçe

Türkçe -

Gaeilge

Gaeilge -

العربية

العربية -

Indonesia

Indonesia -

Norsk

Norsk -

تمل

تمل -

český

český -

ελληνικά

ελληνικά -

український

український -

Javanese

Javanese -

فارسی

فارسی -

தமிழ்

தமிழ் -

తెలుగు

తెలుగు -

नेपाली

नेपाली -

Burmese

Burmese -

български

български -

ລາວ

ລາວ -

Latine

Latine -

Қазақша

Қазақша -

Euskal

Euskal -

Azərbaycan

Azərbaycan -

Slovenský jazyk

Slovenský jazyk -

Македонски

Македонски -

Lietuvos

Lietuvos -

Eesti Keel

Eesti Keel -

Română

Română -

Slovenski

Slovenski -

मराठी

मराठी -

Srpski језик

Srpski језик -

Español

Español -

Português

Português

Home

>

Products > Turning and Milling Combined Machine

>

Inner Three-curve Groove Turning and Milling Machine

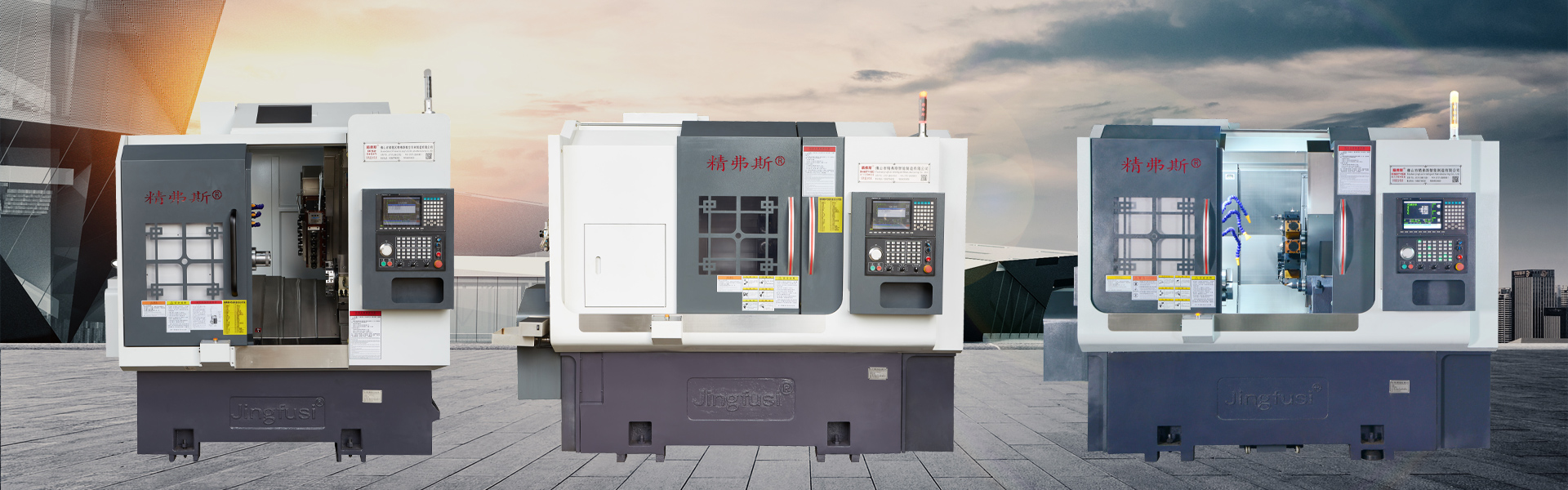

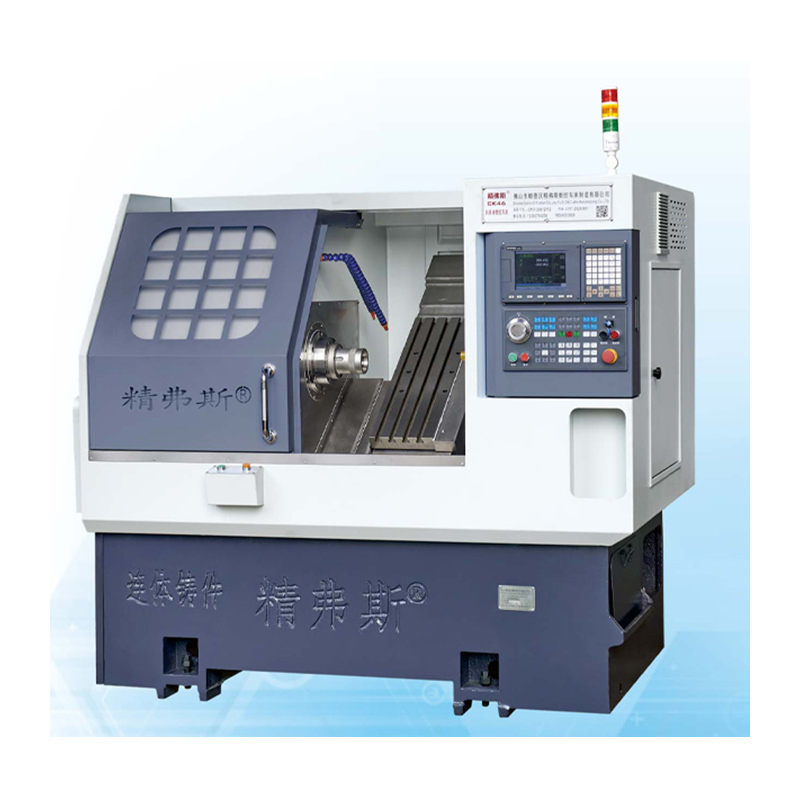

Inner Three-curve Groove Turning and Milling Machine

Jingfusi® Inner Three-curve Groove Turning and Milling Machine is a specialized machining tool used for the precision machining of inner grooves with three curved or contoured surfaces. This Inner Three-curve Groove Turning and Milling Machine is commonly employed in industries that require the production of complex parts with inner grooves or profiles that cannot be easily created using conventional machining methods.

Model:CK46-3+2

Send Inquiry

Product Description

While primarily used for inner groove machining, these machines can also handle other machining operations, making them versatile for a wide range of applications. Industries such as aerospace, medical device manufacturing, automotive, and precision engineering often rely on these machines to produce intricate and high-precision components. Inner Three-curve Groove Turning and Milling Machines can process various materials, including metals, plastics, and composites, depending on the specific machining needs.

Machine Travel Diagram

Product Details

Parameter List

| Item | unit | Specification |

| Max. turning diameter | mm | 250 |

| Max. swing diam. over lathe | mm | Ø500 |

| Max. turning diameter through slide bed | mm | Ø160 |

| Slanting bed degree | degree | 35° |

| X-axis effective travel | mm | 1000 |

| Z-axis effective travel | mm | 400 |

| X/Z axis max. fast travel speed | m/min | 24 |

| Cast iron base area | ㎡ | 1.8 x 1.1 |

| Machine size :L x W x H | mm | 2100x 1580 x 1800 |

| Machine net weight | kg | 2600 |

| tool no. | pcs | 8 |

| Square tools | mm | 20 x 20 |

| Hole knife size | mm | Ø20 |

| Total horse | kw | 13 |

| Average power consumption | kw/h | 2 |

| Spindle face form |

|

A2-5 |

| Spindle speed | r/min | 6000 |

| Spindle speed setting | r/min | 1-4500 |

| Spindle Rated Torque | Nm | 35Nm(1500 r/min) |

| Maximum bar diameter | mm | Ø45 |

Machine Tool Accuracy

| Machine accuracy,Jingfus factor standard : | ||||

| Major test item | Schematic diagram | Factory standard | ||

| Spindle radial beat, |

|

Detect runout of outer cone | 0.0035 | |

| X-axis repeat position,X |

|

Detect repeated positioning of the X-axis. Note: First predict about 50 times to offset the error of the cold engine and hot engine, and then detect the repeated positioning. | 0.003 | |

| Z-axis repeat position,Z |

|

Detect repeated positioning on the Z axis. Note: First predict about 50 times to offset the error of the cold engine and hot engine, and then detect the repeated positioning. | 0.003 | |

| C axis repeat position,C |

|

Detect the repositioning of the C-axis fixed point, note: first predict about 50 times to offset the error of the cold engine and hot engine, and then detect the repeated positioning | 20 arc seconds | |

| C axis position rotary,C |

|

Detect the random position accuracy of the C-axis, note: first predict about 50 times to offset the error of the cold engine and hot engine, and then check the repeated settings | 72 arc seconds | |

| If the customer wants to test the ISO or VD1 accuracy of X/Z/Y axis, it shall be determined at the time of writing the contract. The customer must test this item at the same time of the initial acceptance of Jingfusi Factory. | ||||

Hot Tags: Inner Three-curve Groove Turning and Milling Machine, China, Manufacturers, Suppliers, Factory, Quality, Price List

Send Inquiry

Please feel free to fill your inquiry in the form below. We will reply you in 24 hours.

Related Products

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy