English

English-

English

English -

Français

Français -

日本語

日本語 -

Deutsch

Deutsch -

tiếng Việt

tiếng Việt -

Italiano

Italiano -

Nederlands

Nederlands -

ภาษาไทย

ภาษาไทย -

Polski

Polski -

한국어

한국어 -

Svenska

Svenska -

magyar

magyar -

Malay

Malay -

বাংলা ভাষার

বাংলা ভাষার -

Dansk

Dansk -

Suomi

Suomi -

हिन्दी

हिन्दी -

Pilipino

Pilipino -

Türkçe

Türkçe -

Gaeilge

Gaeilge -

العربية

العربية -

Indonesia

Indonesia -

Norsk

Norsk -

تمل

تمل -

český

český -

ελληνικά

ελληνικά -

український

український -

Javanese

Javanese -

فارسی

فارسی -

தமிழ்

தமிழ் -

తెలుగు

తెలుగు -

नेपाली

नेपाली -

Burmese

Burmese -

български

български -

ລາວ

ລາວ -

Latine

Latine -

Қазақша

Қазақша -

Euskal

Euskal -

Azərbaycan

Azərbaycan -

Slovenský jazyk

Slovenský jazyk -

Македонски

Македонски -

Lietuvos

Lietuvos -

Eesti Keel

Eesti Keel -

Română

Română -

Slovenski

Slovenski -

मराठी

मराठी -

Srpski језик

Srpski језик -

Español

Español -

Português

Português

Home

>

Products > Turning and Milling Combined Machine

>

High-efficiency CNC Turning and Milling Machine

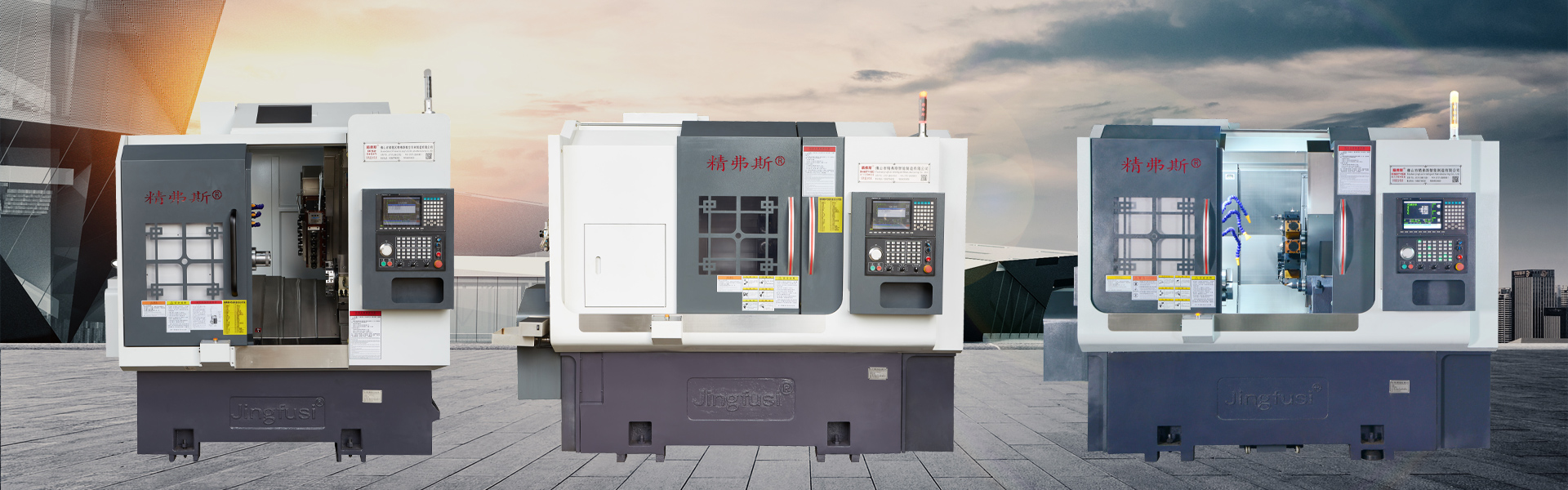

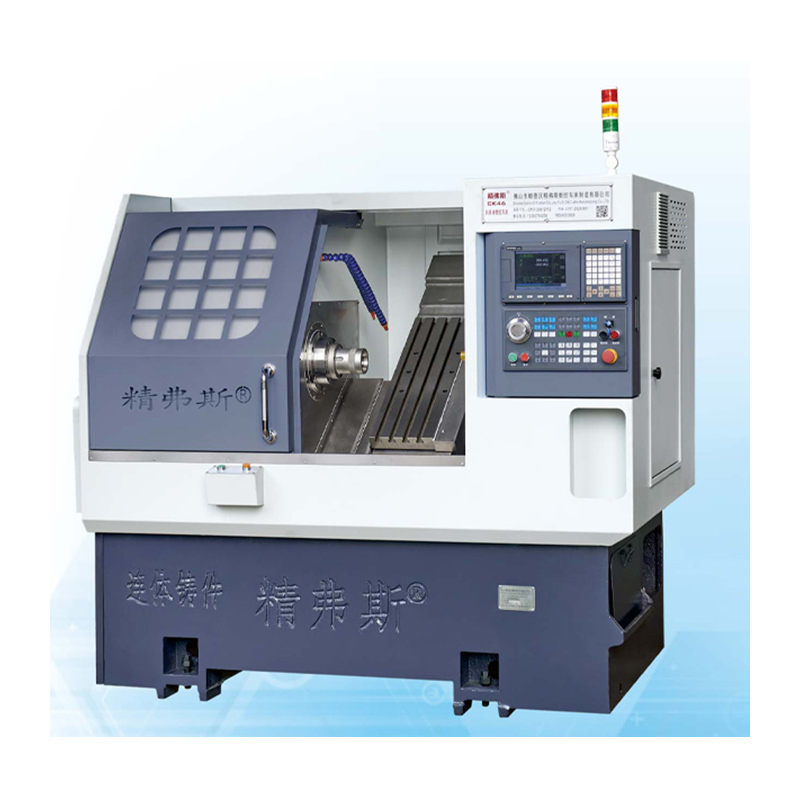

High-efficiency CNC Turning and Milling Machine

The Jingfusi® High-efficiency CNC Turning and Milling Machine features a robust, heavy-duty build and advanced software programming to ensure precision and accuracy with every task. Whether you need to drill holes, cut intricate shapes, or achieve a mirror-like finish on your workpiece, our machine is up to the task.

Model:CK52-5+5+Y

Send Inquiry

Product Description

One of the key benefits of our Jingfusi® High-efficiency CNC Turning and Milling Machine is its versatility. With a range of tooling options available, our machine can perform a variety of turning, milling, and drilling operations, making it the perfect choice for small scale production or larger-scale manufacturing projects.

User-Friendly Interface

Don't let its advanced capabilities intimidate you. Our High-efficiency CNC Turning and Milling Machine boasts an intuitive user interface that makes it easy for professionals of all experience levels to operate. With an interactive touchscreen display and user-friendly software, you can program and execute even the most complex tasks with confidence.

Efficient Workflow

At the heart of our machine's design is an emphasis on efficiency. The machine can be programmed to perform multiple tasks in a single cycle, reducing production time and increasing throughput. Additionally, our machine features a high-speed spindle that enables faster cutting speeds, thus further improving productivity.

Rugged Durability

We understand that reliability is a top priority for our customers. That's why we've constructed our High-efficiency CNC Turning and Milling Machine with rugged, durable materials that can stand up to heavy use. Plus, regular maintenance and upkeep are straightforward, making it easy to keep your machine in top operating condition for years to come.

In conclusion, our Jingfusi® High-efficiency CNC Turning and Milling Machine is a powerful and versatile tool that can help automate your manufacturing processes and improve efficiency. Whether you're producing large-scale runs or custom, one-of-a-kind parts, our machine can help you achieve excellent quality results with ease. Contact us today to arrange a demo and see for yourself what our product can do for you.

Machine Travel Diagram

Product Details

Parameter List

| item | content | unit | CK46-5+5+Y | CK52-5+5+Y |

| Processing scope | Swing over bed | mm | Ø 500 | |

| Maximum turning outer circle length | mm | 320 | ||

Maximum bar diameter | mm | Ø 45 | Ø 51 ~ 55 | |

| principal axis | Maximum spindle speed | r/min | 6000(set to 4000) | 4500 (set to 3500) |

| Spindle head type | A2 - 5 | A2 - 6 | ||

| Spindle through-hole diameter | mm | Ø 56 | Ø 66 | |

| feed | X/Z/Y axis maximum stroke | mm | 800/470/310 | |

| Maximum fast movement of X/Z/Y axis | m/min | 24 (Setting 18)/24 (Setting 18)/15 (Setting 8) | ||

| X/Z/Y axis screw rod | mm | 32/32/25 | ||

| X/Z/Y axis rail | mm | 35/35/25 | ||

| Knife tower | Eight station turret | PCS | 8 stations, can be equipped with double hole tool holders, optional with 12 stations | |

| Power head | Power head tool holding form | ER25 | ||

| Maximum speed of power head | r/min | 6000 (set to 4000), can be commonly used to process products from 4000 | ||

| Maximum installation drilling and milling head diameter | mm | Ø 16 | ||

| Distance between power head shaft and shaft | mm | 65 | ||

| electrical machinery | Main motor power/torque | KW/Nm | 7.5 KW/47.75NM, optional 11KW/70.03Nm for steel parts with a processing capacity of 80 and above | |

| X/Z/Y axis motor power/torque | KW/Nm | Yaskawa 1.8KW/11.5Nm. Optional new generation 2.4 KW/rated 11.5Nm | ||

| X/Z power head motor power/torque | KW/Nm | 2.4 KW/11.5NM | ||

| Maximum speed of power head motor | r/min | 5000 | ||

| other | Spindle positioning brake device | hydraulic pressure | ||

| Bed inclination | ° | 35° | ||

| Knife table plate length X width | mm | 700X290 | ||

| Machine tool length X width X height | mm | 2200X1580X2000 | ||

| Total weight of the entire machine | KG | 3430 | ||

| Total power | kw | 13 | ||

| Average power consumption | kw/h | 2 | ||

Machine Tool Accuracy

| Machine accuracy,Jingfus factor standard : | ||||||||

| Major test item | Schematic diagram | Factory standard | ||||||

| Spindle radial beat |  | Detect runout of outer cone | 0.0035 | |||||

| X-axis repeat position |  | Detect repeated positioning of the X-axis. Note: First predict about 50 times to offset the error of the cold engine and hot engine, and then detect the repeated positioning. | 0.003 | |||||

| Z-axis repeat position |  | Detect repeated positioning on the Z axis. Note: First predict about 50 times to offset the error of the cold engine and hot engine, and then detect the repeated positioning. | 0.003 | |||||

| Y-axis repeat position |  | Detect repeated positioning on the Y axis. Note: First predict about 50 times to offset the error of the cold engine and hot engine, and then detect the repeated positioning. | 0.004 | |||||

| C axis repeat position |  | Detect the repositioning of the C-axis fixed point, note: first predict about 50 times to offset the error of the cold engine and hot engine, and then detect the repeated positioning | 20 arc seconds | |||||

| C axis position rotary |  | Detect the random position accuracy of the C-axis, note: first predict about 50 times to offset the error of the cold engine and hot engine, and then check the repeated settings | 72 arc seconds | |||||

| Power head clamping beat |  | Cone beat | 0.015 | |||||

| Power head clamping beat |  | Clamping beating | 0.01 | |||||

| If the customer wants to test the ISO or VD1 accuracy of X/Z/Y axis, it shall be determined at the time of writing the contract. The customer must test this item at the same time of the initial acceptance of Jingfusi Factory. | ||||||||

Hot Tags: High-efficiency CNC Turning and Milling Machine, China, Manufacturers, Suppliers, Factory, Quality, Price List

Send Inquiry

Please feel free to fill your inquiry in the form below. We will reply you in 24 hours.

Related Products

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy