English

English-

English

English -

Français

Français -

日本語

日本語 -

Deutsch

Deutsch -

tiếng Việt

tiếng Việt -

Italiano

Italiano -

Nederlands

Nederlands -

ภาษาไทย

ภาษาไทย -

Polski

Polski -

한국어

한국어 -

Svenska

Svenska -

magyar

magyar -

Malay

Malay -

বাংলা ভাষার

বাংলা ভাষার -

Dansk

Dansk -

Suomi

Suomi -

हिन्दी

हिन्दी -

Pilipino

Pilipino -

Türkçe

Türkçe -

Gaeilge

Gaeilge -

العربية

العربية -

Indonesia

Indonesia -

Norsk

Norsk -

تمل

تمل -

český

český -

ελληνικά

ελληνικά -

український

український -

Javanese

Javanese -

فارسی

فارسی -

தமிழ்

தமிழ் -

తెలుగు

తెలుగు -

नेपाली

नेपाली -

Burmese

Burmese -

български

български -

ລາວ

ລາວ -

Latine

Latine -

Қазақша

Қазақша -

Euskal

Euskal -

Azərbaycan

Azərbaycan -

Slovenský jazyk

Slovenský jazyk -

Македонски

Македонски -

Lietuvos

Lietuvos -

Eesti Keel

Eesti Keel -

Română

Română -

Slovenski

Slovenski -

मराठी

मराठी -

Srpski језик

Srpski језик -

Español

Español -

Português

Português

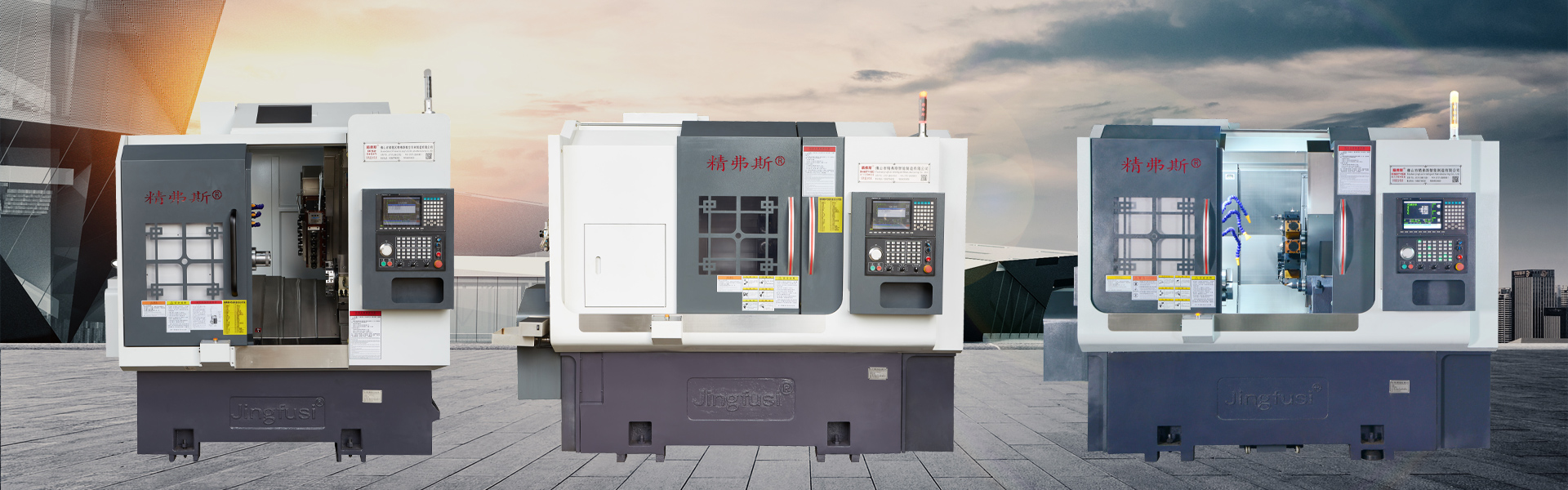

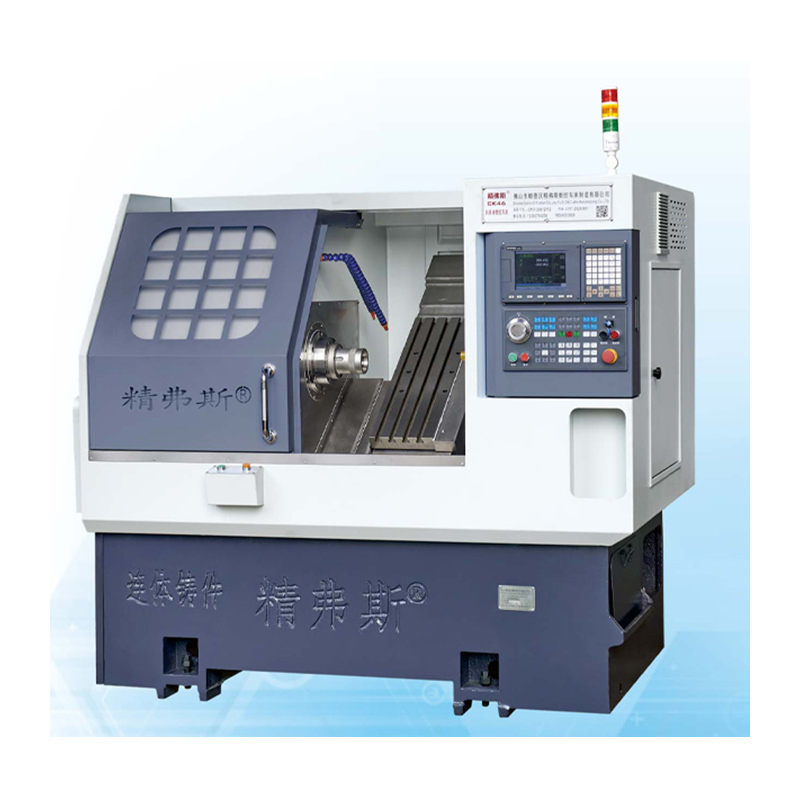

CNC Multi-tasking Turning Center Machine

Introducing the CNC Multi-tasking Turning Center Machine – the ultimate solution for high-quality precision machining. This powerful machine has been designed to meet the demands of even the most complex turning applications, making it an ideal choice for businesses that require the highest levels of accuracy and efficiency.

Model:CK52-5+5+Y

Send Inquiry

Built to last, the CNC Multi-tasking Turning Center Machine is a durable and reliable machine that is capable of handling a wide range of tasks – from simple turning and drilling operations to more complex tasks such as milling, thread cutting and more.

One of the key features of the CNC Multi-tasking Turning Center Machine is its advanced control system, which allows operators to easily program and control every aspect of the machining process, ensuring maximum precision and accuracy. With its user-friendly interface, this machine is easy to use and can be quickly adapted to suit the needs of any job.

In addition to its advanced control system, the CNC Multi-tasking Turning Center Machine also boasts a range of high-quality components, including an advanced spindle system, high-precision linear guides and a durable, cast iron base. These components work in perfect harmony to ensure that every job is completed to the highest standard.

Whether you are a small business or a larger corporation, the CNC Multi-tasking Turning Center Machine is the perfect choice for all your machining needs. With its advanced features, durable construction and exceptional precision, this machine is sure to exceed your expectations and provide you with years of reliable, high-quality performance.

In conclusion, the CNC Multi-tasking Turning Center Machine is a top-of-the-line solution for businesses that demand the very best in precision machining. With its advanced features, user-friendly interface and reliable construction, it is sure to provide you with years of reliable and efficient performance. So why wait? Contact us today to learn more about this incredible machine and how it can transform your business.

| item | content | unit | CK46-5+5+Y | CK52-5+5+Y |

| Processing scope | Swing over bed | mm | Ø 500 | |

| Maximum turning outer circle length | mm | 320 | ||

|

Maximum bar diameter |

mm | Ø 45 | Ø 51 ~ 55 | |

| principal axis | Maximum spindle speed | r/min | 6000(set to 4000) | 4500 (set to 3500) |

| Spindle head type |

|

A2 - 5 | A2 - 6 | |

| Spindle through-hole diameter | mm | Ø 56 | Ø 66 | |

| feed | X/Z/Y axis maximum stroke | mm | 800/470/310 | |

| Maximum fast movement of X/Z/Y axis | m/min | 24 (Setting 18)/24 (Setting 18)/15 (Setting 8) | ||

| X/Z/Y axis screw rod | mm | 32/32/25 | ||

| X/Z/Y axis rail | mm | 35/35/25 | ||

| Knife tower | Eight station turret | PCS | 8 stations, can be equipped with double hole tool holders, optional with 12 stations | |

| Power head | Power head tool holding form |

|

ER25 | |

| Maximum speed of power head | r/min | 6000 (set to 4000), can be commonly used to process products from 4000 | ||

| Maximum installation drilling and milling head diameter | mm | Ø 16 | ||

| Distance between power head shaft and shaft | mm | 65 | ||

| electrical machinery | Main motor power/torque | KW/Nm | 7.5 KW/47.75NM, optional 11KW/70.03Nm for steel parts with a processing capacity of 80 and above | |

| X/Z/Y axis motor power/torque | KW/Nm | Yaskawa 1.8KW/11.5Nm. Optional new generation 2.4 KW/rated 11.5Nm | ||

| X/Z power head motor power/torque | KW/Nm | 2.4 KW/11.5NM | ||

| Maximum speed of power head motor | r/min | 5000 | ||

| other | Spindle positioning brake device |

|

hydraulic pressure | |

| Bed inclination | ° | 35° | ||

| Knife table plate length X width | mm | 700X290 | ||

| Machine tool length X width X height | mm | 2200X1580X2000 | ||

| Total weight of the entire machine | KG | 3430 | ||

| Total power | kw | 13 | ||

| Average power consumption | kw/h | 2 | ||

| Machine accuracy,Jingfus factor standard : | ||||||||

| Major test item | Schematic diagram | Factory standard | ||||||

| Spindle radial beat |

|

Detect runout of outer cone | 0.0035 | |||||

| X-axis repeat position |

|

Detect repeated positioning of the X-axis. Note: First predict about 50 times to offset the error of the cold engine and hot engine, and then detect the repeated positioning. | 0.003 | |||||

| Z-axis repeat position |

|

Detect repeated positioning on the Z axis. Note: First predict about 50 times to offset the error of the cold engine and hot engine, and then detect the repeated positioning. | 0.003 | |||||

| Y-axis repeat position |

|

Detect repeated positioning on the Y axis. Note: First predict about 50 times to offset the error of the cold engine and hot engine, and then detect the repeated positioning. | 0.004 | |||||

| C axis repeat position |

|

Detect the repositioning of the C-axis fixed point, note: first predict about 50 times to offset the error of the cold engine and hot engine, and then detect the repeated positioning | 20 arc seconds | |||||

| C axis position rotary |

|

Detect the random position accuracy of the C-axis, note: first predict about 50 times to offset the error of the cold engine and hot engine, and then check the repeated settings | 72 arc seconds | |||||

| Power head clamping beat |

|

Cone beat | 0.015 | |||||

| Power head clamping beat |

|

Clamping beating | 0.01 | |||||

| If the customer wants to test the ISO or VD1 accuracy of X/Z/Y axis, it shall be determined at the time of writing the contract. The customer must test this item at the same time of the initial acceptance of Jingfusi Factory. | ||||||||