English

English-

English

English -

Français

Français -

日本語

日本語 -

Deutsch

Deutsch -

tiếng Việt

tiếng Việt -

Italiano

Italiano -

Nederlands

Nederlands -

ภาษาไทย

ภาษาไทย -

Polski

Polski -

한국어

한국어 -

Svenska

Svenska -

magyar

magyar -

Malay

Malay -

বাংলা ভাষার

বাংলা ভাষার -

Dansk

Dansk -

Suomi

Suomi -

हिन्दी

हिन्दी -

Pilipino

Pilipino -

Türkçe

Türkçe -

Gaeilge

Gaeilge -

العربية

العربية -

Indonesia

Indonesia -

Norsk

Norsk -

تمل

تمل -

český

český -

ελληνικά

ελληνικά -

український

український -

Javanese

Javanese -

فارسی

فارسی -

தமிழ்

தமிழ் -

తెలుగు

తెలుగు -

नेपाली

नेपाली -

Burmese

Burmese -

български

български -

ລາວ

ລາວ -

Latine

Latine -

Қазақша

Қазақша -

Euskal

Euskal -

Azərbaycan

Azərbaycan -

Slovenský jazyk

Slovenský jazyk -

Македонски

Македонски -

Lietuvos

Lietuvos -

Eesti Keel

Eesti Keel -

Română

Română -

Slovenski

Slovenski -

मराठी

मराठी -

Srpski језик

Srpski језик -

Español

Español -

Português

Português

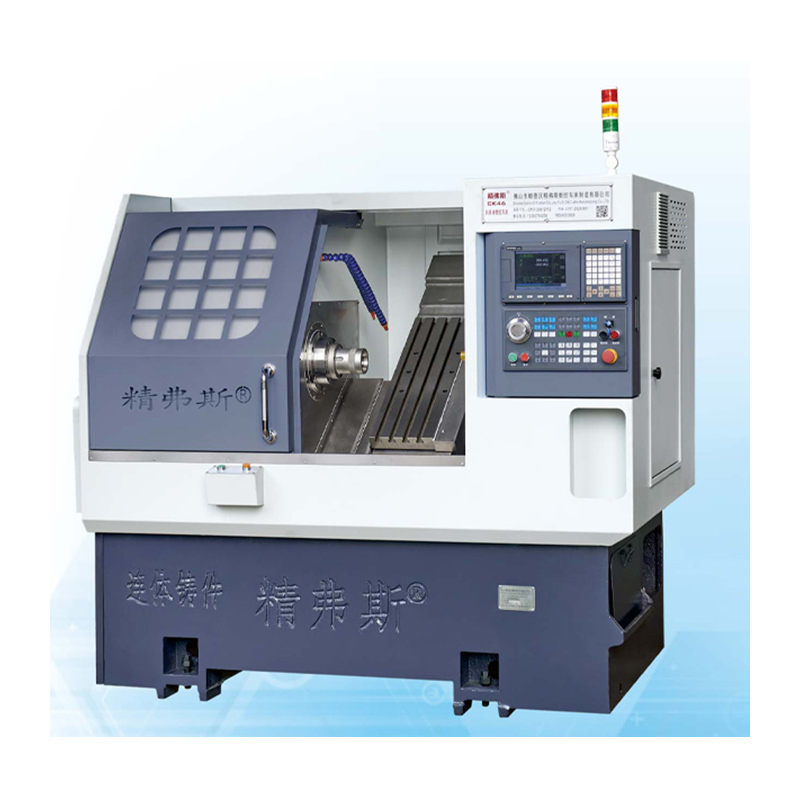

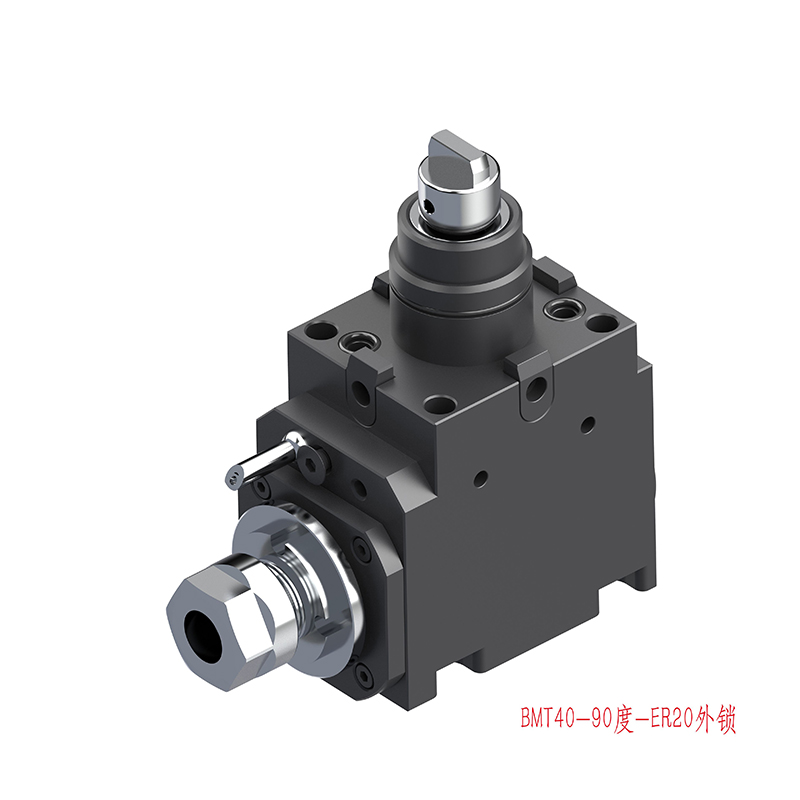

Static Boring Tool Holder for CNC

Feel confident in purchasing customized Static Boring Tool Holders for CNC from Jingfusi®. We eagerly anticipate the opportunity to work with you. Should you have any further inquiries, please do not hesitate to contact us, and we will respond promptly!

Model:BMT40-ERA20-90

Send Inquiry

Static Boring Tool Holder for CNC advantages:

In CNC machining, having the right tool holder is essential to achieving precision, efficiency, and cost-effectiveness. Static Boring Tool Holder for CNC stands out in several key areas.

First, their high quality is reflected in their sturdy construction and precision engineering. This ensures that the tool holder can meet the rigorous requirements of CNC machining, providing stable and reliable performance for a long time.

Second, Static Boring Tool Holder for CNC is relatively more economical and durable. Its efficient design and material selection help minimize costs, making them the choice of various businesses and workshops.

In addition, the tool holder provides longer tool life. This is achieved through its precision fit and stability, which reduces tool wear.

Finally, Static Boring Tool Holder for CNC helps reduce overall costs. By improving precision, efficiency, and tool life, it can reduce scrap rates, increase productivity, and reduce maintenance costs. All of these factors help reduce the cost per part, making your CNC machining operation more profitable.

Collect type : internal diameter locking

Maximum speed : RPM 5000

Collect dimater : Ø1-Ø13

Wight : 4.1 kgs

Precision : inner collect hole run-out less than 0.01mm

With coolant supply through the tool holder

| Item: | Static Boring Tool Holder for CNC |

| Process Type: | CNC machining, CNC lathe, cleaning edge, grinding, surface treatment, coloring.etc. |

| Material: | Cr, CrMo or other Imported or China domestic standard specified material. |

| Tolerance: | +-0.01mm as per requirement or customized reqiurement |

| Surface treatment: | Spray, Polishing, Powder coating and Electroplating,other customer specified treatment. |

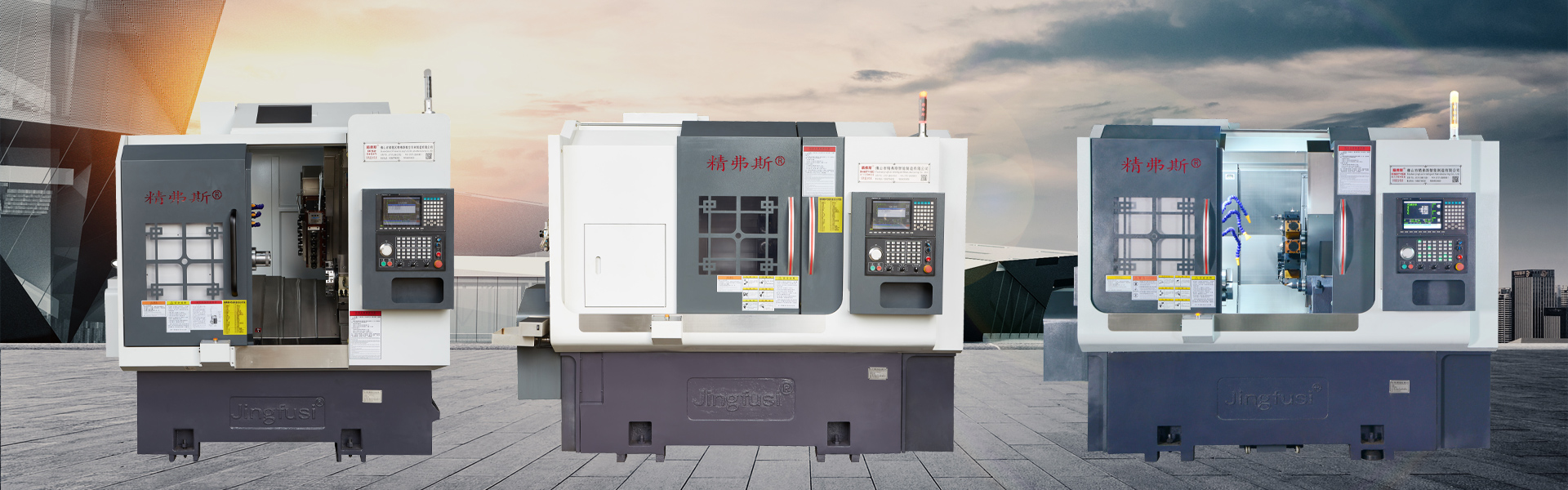

| Facility: | DMG CNC Machining Center, CNC Turning Machine, CNC Vertical lathe, 4-Axis CNC Machine, Grinding machine and so on |

| Certificates: | Material certificate, QC reports, Surface treatment inspection reports, other customer required certificates are available to provide. |

| Shipping: |

Sample 5~10days lead time. By DHL/TNT/FedEx express, air freight etc. Production 15 days about |

| Delivery & Service: | Timely delivery each time. Provide reliable service and responsible for each customer with each product. Our target is to satisfy every customer with the best service. |

2. In processing inspection

3. Final inspection

4. Outgoing inspection

A: To start your project, please send us the design drawings with a list of material, quantity and finish. Then, you will get the quotation from us within 24 hours.

Q: Which surface treatment are the most common for metal parts?

A: Polishing, Black Oxide , Anodized, Powder Coating, Sandblasting, Painting , all kinds of plating(copper plating, chrome plating, nickel plating, gold plating, silver plating…)…

Q: We’re not familiar with the international transport, will you handle all the logistic thing?

A: Definitely. Many years experience and long term cooperated forwarder will full support us on it. You can only inform us the delivery date, and then you will receive the goods at office/home. Other concerns leave to us.